ABS Material Plastic Injection Molding

Basic Info

Model No.: MLD-14-P002

Product Description

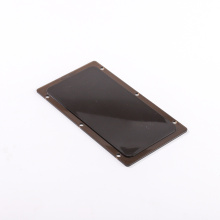

Model NO.: MLD-14-P002 Mould Standard: Hasco, Dme, Misumi, Punch Mould Life: 500,000shots Product Material: :ABS, ABS V0, PC, PC V0, PC+ABS, PP, etc Runner: Hot / Cold Export Markets: Global Specification: ISO 9001: 2008 Certificated HS Code: 39269010 Material: ABS Design Software: Ug, PRO/E, Powmill, Autocad Mould Base: Lkm / Hasco /Dme, etc Lead Time: 3~5weeks Package: Wooden CAS, PP Bag Trademark: MOLDIE Origin: Ningbo, China Specifications

1. OEM/ODM service

2. Quick delivery

3. Competitive price

4. Strict quality control system

5. Experienced with US. And Europe

OEM & ODM by customers' design, quote according to your drawing and samples

Our engineer team manage from part drawing until shipment and check each step to make sure the final Products are qualified before shipment.

MOLDIE with its factory has more than 10 years experience for various mechanical Stamping parts.

"Good quality" is the base of MOLDIE business, as all MOLDIE staff know quality is essential Condition for mechanical products, MOLDIE must keep our clients in a safe condition.

ISO 9001: 2008 certificated.

Since 2007, MOLDIE starts exporting various plastic parts to Germany, Spain, Italy, USA and so on.

Our engineer team manage from part drawing until shipment and check each step to make Sure the final products are qualified before shipment.

To he plastic products, we also can make the mold for your products, and we will send the Sample to you, we will start produce the products after you are satisfied with the sample.

Advantages:

1. Quick delivery

2. Low quantity is acceptable

3. Strict quality control system.

4. Advanced equipment, excellent R&D teams

5. Professional technicians and rich experienced workers.

Contact us if you need more details on Molding. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Molding Parts、Injection Molding. If these products fail to match your need, please contact us and we would like to provide relevant information.

1. OEM/ODM service

2. Quick delivery

3. Competitive price

4. Strict quality control system

5. Experienced with US. And Europe

OEM & ODM by customers' design, quote according to your drawing and samples

Our engineer team manage from part drawing until shipment and check each step to make sure the final Products are qualified before shipment.

MOLDIE with its factory has more than 10 years experience for various mechanical Stamping parts.

"Good quality" is the base of MOLDIE business, as all MOLDIE staff know quality is essential Condition for mechanical products, MOLDIE must keep our clients in a safe condition.

ISO 9001: 2008 certificated.

Since 2007, MOLDIE starts exporting various plastic parts to Germany, Spain, Italy, USA and so on.

Our engineer team manage from part drawing until shipment and check each step to make Sure the final products are qualified before shipment.

To he plastic products, we also can make the mold for your products, and we will send the Sample to you, we will start produce the products after you are satisfied with the sample.

Advantages:

1. Quick delivery

2. Low quantity is acceptable

3. Strict quality control system.

4. Advanced equipment, excellent R&D teams

5. Professional technicians and rich experienced workers.

| Business Mode | OEM, ODM, OBM |

| Mold Base | LKM, C50 standard mold base, etc. |

| Mold Material | DIN2312,2738,2344,718,S136,S136H,8407,NAK80,SKD61,H13 |

| Standard | HASCO, DME, MISUMI, PUNCH |

| Product Material | PA,PA6/6+GF,ABS,POM,PC,PP,PMMA,PS,PVC,HDPE etc |

| Cavity | 1~32 cavity |

| Shot Runner | Cold/hot |

| Surface Finishing | EDM, High Polish |

| Hardness of steel | 46~56HRC |

| Maximun Mould size | Width 600mm to 1600mm |

| Value-added service | Polish,texture, painting, screen printing, turnkey project. |

| Mould Life | 300,000~500,000 shots |

| Package | Rust-proof protection, Wooden/Plywood case for the mould , Pallte, PE bags, bubble/foam pack for the injecton molding parts. |

| Lead time | 3~5days for hand sample; 2~6weeks for mould design&manufacturing; 3~5days for plastic molding. |

| Certification | ISO 9001:2008 |

Contact us if you need more details on Molding. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Molding Parts、Injection Molding. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Plastic injection parts > Others Plastic injection parts

Premium Related Products

Other Products

Hot Products

Hexagon socket head cap screwsstainless steel tapping screw/ hexgan/flat/pan/square head bolt/hexgon socket head cap screw/ screw with washerCNC milling machined service parts stainless steel partPrecision casting turing milling machined rotor and stator for oil drilling, oil pump, submersible pump, farm machineryOEM/ODM customized cnc lathe turning machine precision parts/cnc maching parts/cnc metal lathe part/cnc lathe engines partsAluminum extrusion profile, aluminum extrusion radiator framecnc machining part of 6061 Aluminum for circuit board wrenchPlastic injection molding machine, Plastic Injection Mould Shaping Mould designElectrical Discharge Machining used electrocorrosion wire copper electrodeauto alternator housing serieszinc pot12v starter capsaluminum alternator bracketaluminum die-cast partbearing end-shield for starterauto alternator housing