185T Small Injection Molding Machine

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

|---|---|

| Terms of Trade: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 30 Days |

| Packaging: | Plastic Film |

|---|---|

| Brand: | Winiber |

| Transportation: | Ocean |

| Place of Origin: | China |

| Supply Ability: | 10 Sets/Month |

| Port: | NINGBO,SHANGHAI |

Basic Info

Model No.: WB-185F

Click on the follow link to find out more information: https://www.winiber-machinery.com/fixed-pump-injection-molding-machine/

Company Info

- Company Name: WENZHOU WINIBER MACHINERY EQUIPMENT CO., LTD.

- Product/Service: PET Blowing Machine , PET Preform Mould , Bottle Blowing Machine , Filling Machine , Bottle Production Line , Water Production Line

- Year Established: 2011

- Total Annual Sales Volume (Million US $): US$2.5 Million - US$5 Million

- Export Percentage: 91% - 100%

- No. of R&D Staff: 5 -10 People

- No. of QC Staff: 5 -10 People

- Factory Size (Sq.meters): 1,000-3,000 square meters

- Contact Person: Ms. Wini Zhou

- Tel: 86-0577-83531938

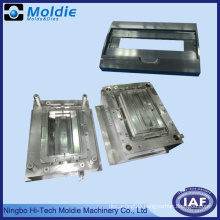

Premium Related Products

Other Products

Hot Products

Hexagon socket head cap screwsstainless steel tapping screw/ hexgan/flat/pan/square head bolt/hexgon socket head cap screw/ screw with washerCNC milling machined service parts stainless steel partPrecision casting turing milling machined rotor and stator for oil drilling, oil pump, submersible pump, farm machineryOEM/ODM customized cnc lathe turning machine precision parts/cnc maching parts/cnc metal lathe part/cnc lathe engines partsAluminum extrusion profile, aluminum extrusion radiator framecnc machining part of 6061 Aluminum for circuit board wrenchPlastic injection molding machine, Plastic Injection Mould Shaping Mould designElectrical Discharge Machining used electrocorrosion wire copper electrodeauto alternator housing serieszinc pot12v starter capsaluminum alternator bracketaluminum die-cast partbearing end-shield for starterauto alternator housing