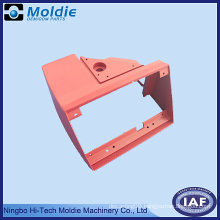

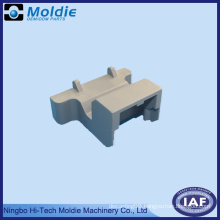

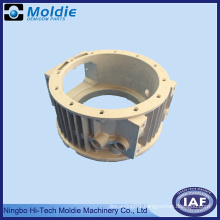

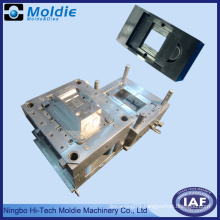

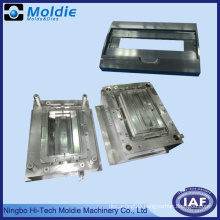

China Mold for Plastic Injection Process

Product Description

Shaping Mode: Injection Mould Mould Cavity: Single Cavity Process Combination Type: Single-Process Mode Runner: Cold Runner Installation: Fixed Standard: HASCO Material: P20 Specification: ISO 9001: 2008 Certificated HS Code: 8480719090 Surface Finish Process: Polishing Plastic Material: POM Application: Household Appliances, Furniture, Electronic Design Software: UG Certification: ISO Customized: Customized Trademark: Moldie Origin: Ningbo, China

1. Custom molds

2. Reasonable price

3. Good at Automotive mold

4. ISO 9001: 2008 Certificated

5. With Europe market since 2004

MOLDIE specializes in manufacturing and supplying of prototypes and various Moulds and dies, such as plastic injection moulds, Die Casting molds and progressive dies since 2004.

MOLDIE provides various molds & dies to the clients from Germany, USA, Spain, Italy, Russia and so on.

"Good quality" is the base of MOLDIE business, as all MOLDIE staff know quality is essential condition for mechanical products, MOLDIE must keep our clients in a safe condition.

ISO 9001: 2008 certificated.

Advantages:

1. Competitive price

2. Strict quality control system

3. Quick mold making and delivery

4. Advanced equipment, excellent R&D teams

5. Professional technicians and rich experienced workers

Special info.:

Following customers' requirement to make the molds.

Mold base: LKM C50 standard mould base

Inserts(cavity and core): H13, 1.2344, 1.2738, 1.2083, 1.2311, NAK80 or the material you required.

Standard parts: HASCO, DME, MISUMI, Punch

Part material: ABS, ABS/PC, PA, PA66+30GF, PBT, PC, POM, PP, PE, PVC and so on

Lead time of first samples: Around 4~7weeks.

We have one professional engineers team to design the mold and check the design to make sure all are right before production. My engineers follow the molds' production every week to make sure all of them are in schedule; After trial production, we will check the samples about the finishing and dimension to make sure samples are right or not and make report to our clients; We do the final inspection on molds before mold shipment. We are one of professional company to provide you good quality molds with good price in time.

Packaging Details: Carton and pallet, rust-proof protection. Suitable for sea shipment and air shipment and easy to be carried by forklift Contact us if you need more details on China Mold for Plastic Injection Process. We are ready to answer your questions on packaging, logistics, certification or any other aspects about China Mold、China Mold Making. If these products fail to match your need, please contact us and we would like to provide relevant information.

1. Custom molds

2. Reasonable price

3. Good at Automotive mold

4. ISO 9001: 2008 Certificated

5. With Europe market since 2004

MOLDIE specializes in manufacturing and supplying of prototypes and various Moulds and dies, such as plastic injection moulds, Die Casting molds and progressive dies since 2004.

MOLDIE provides various molds & dies to the clients from Germany, USA, Spain, Italy, Russia and so on.

"Good quality" is the base of MOLDIE business, as all MOLDIE staff know quality is essential condition for mechanical products, MOLDIE must keep our clients in a safe condition.

ISO 9001: 2008 certificated.

Advantages:

1. Competitive price

2. Strict quality control system

3. Quick mold making and delivery

4. Advanced equipment, excellent R&D teams

5. Professional technicians and rich experienced workers

Special info.:

Following customers' requirement to make the molds.

Mold base: LKM C50 standard mould base

Inserts(cavity and core): H13, 1.2344, 1.2738, 1.2083, 1.2311, NAK80 or the material you required.

Standard parts: HASCO, DME, MISUMI, Punch

Part material: ABS, ABS/PC, PA, PA66+30GF, PBT, PC, POM, PP, PE, PVC and so on

Lead time of first samples: Around 4~7weeks.

We have one professional engineers team to design the mold and check the design to make sure all are right before production. My engineers follow the molds' production every week to make sure all of them are in schedule; After trial production, we will check the samples about the finishing and dimension to make sure samples are right or not and make report to our clients; We do the final inspection on molds before mold shipment. We are one of professional company to provide you good quality molds with good price in time.

Packaging Details: Carton and pallet, rust-proof protection. Suitable for sea shipment and air shipment and easy to be carried by forklift Contact us if you need more details on China Mold for Plastic Injection Process. We are ready to answer your questions on packaging, logistics, certification or any other aspects about China Mold、China Mold Making. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Plastic injection mould > Electrical appliance parts mould

Premium Related Products

Other Products

Hot Products

Hexagon socket head cap screwsstainless steel tapping screw/ hexgan/flat/pan/square head bolt/hexgon socket head cap screw/ screw with washerCNC milling machined service parts stainless steel partPrecision casting turing milling machined rotor and stator for oil drilling, oil pump, submersible pump, farm machineryOEM/ODM customized cnc lathe turning machine precision parts/cnc maching parts/cnc metal lathe part/cnc lathe engines partsAluminum extrusion profile, aluminum extrusion radiator framecnc machining part of 6061 Aluminum for circuit board wrenchPlastic injection molding machine, Plastic Injection Mould Shaping Mould designElectrical Discharge Machining used electrocorrosion wire copper electrodeauto alternator housing serieszinc pot12v starter capsaluminum alternator bracketaluminum die-cast partbearing end-shield for starterauto alternator housing